Cold Storage

Our cold storage facilities offer flexible selection of three core insulation panels: high-density polyurethane (PU) panels, XPS extruded panels, and clean-type/stainless steel panels, tailored to diverse budget and application scenarios. The mainstream PU panels deliver outstanding thermal insulation, while the clean-type panels meet stringent hygiene standards. All panel types fully comply with food-grade safety standards and HACCP requirements.

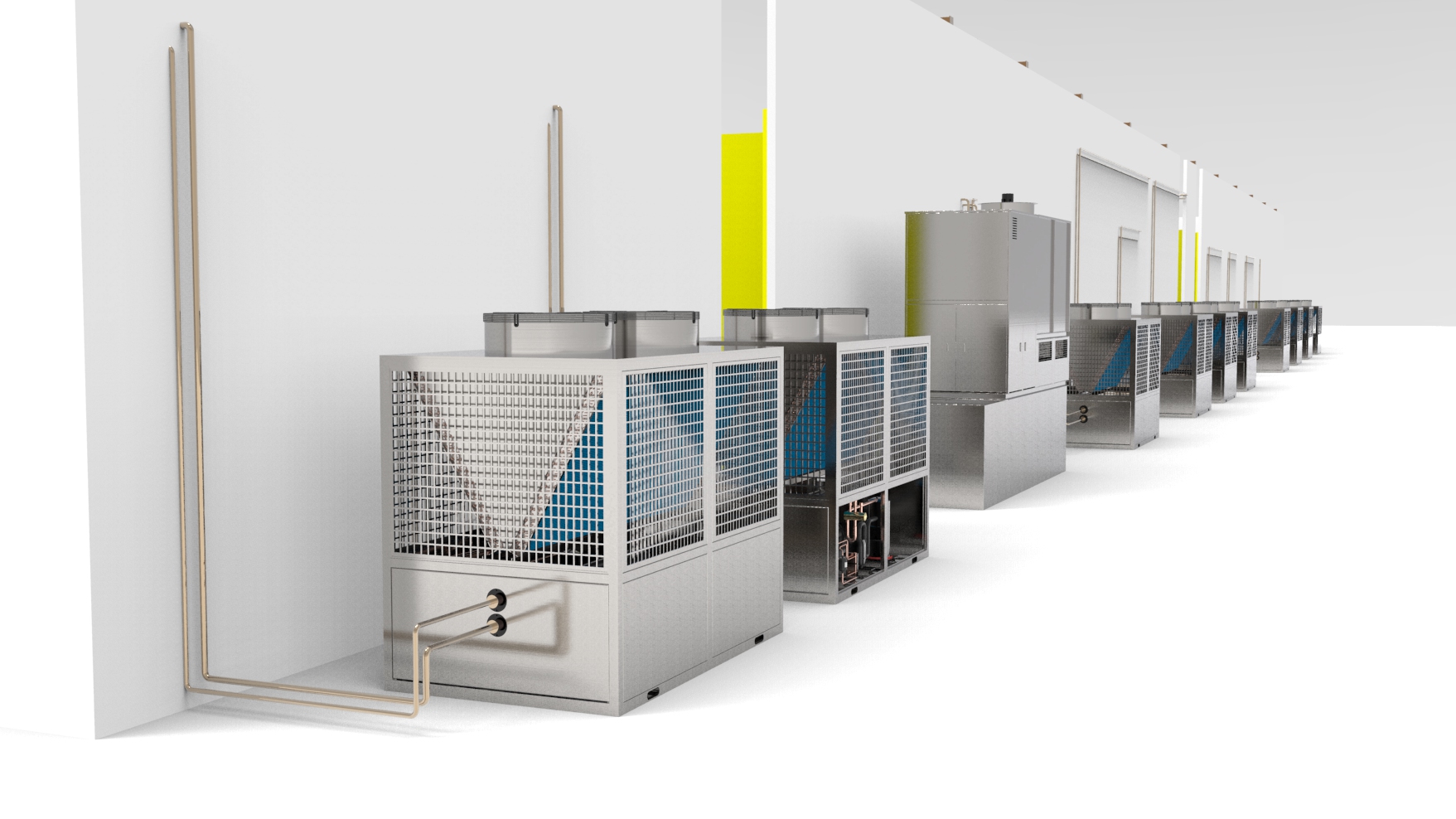

For compressors, we provide flexible configuration of renowned brands such as Bitzer, Italian or Japanese brands, precisely matching the budget of different projects.

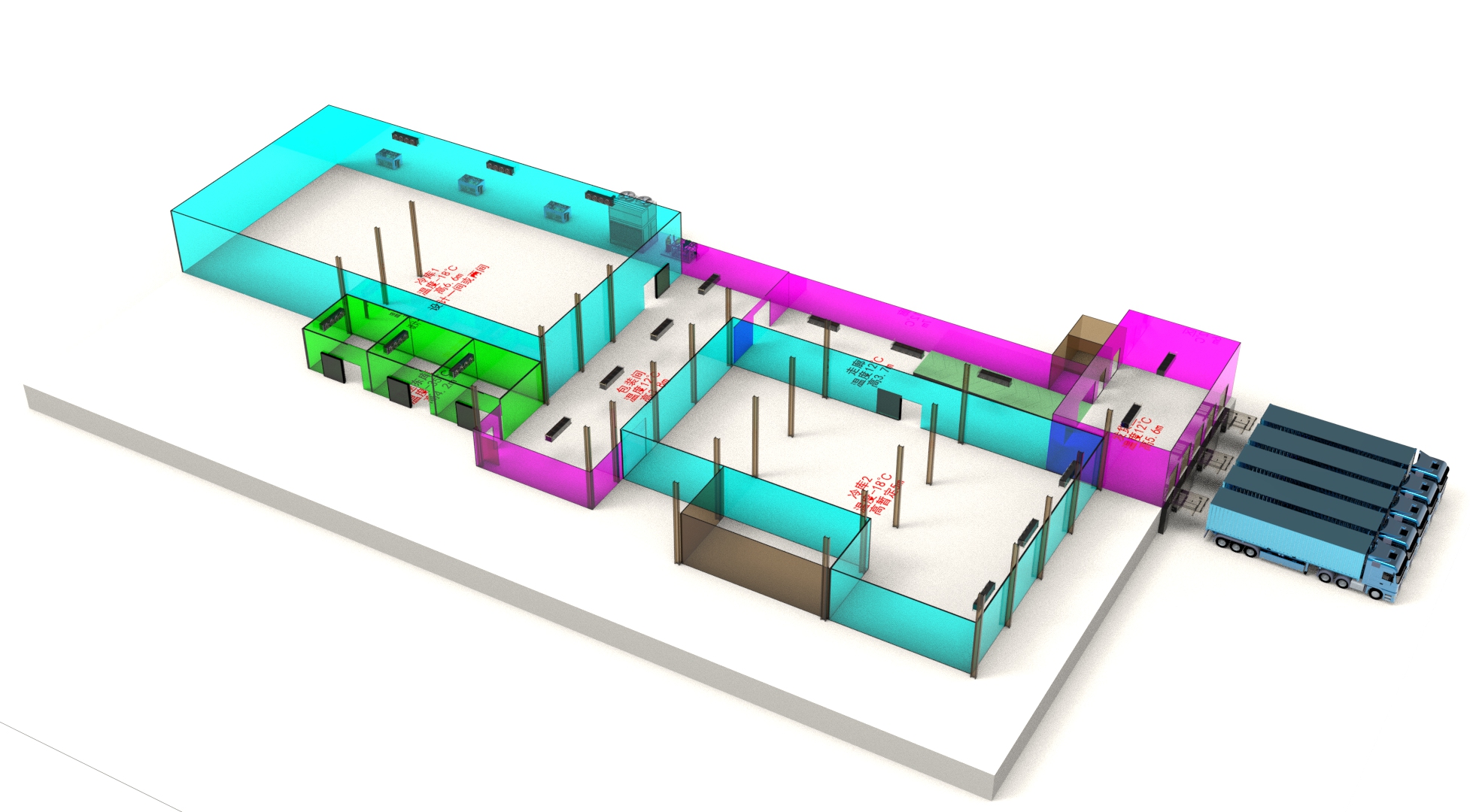

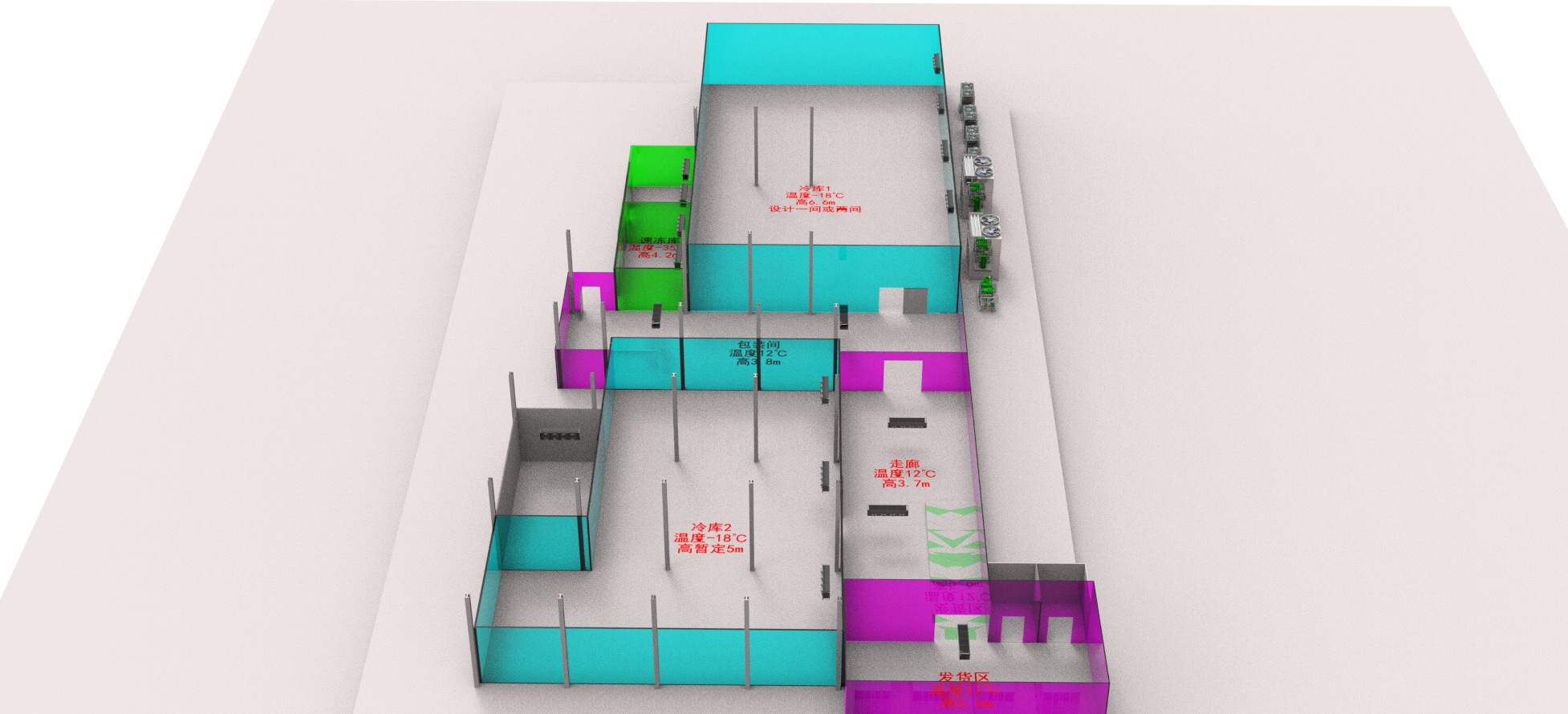

Quick - freeze room: - 30℃

For rapid freezing of meat, aquatic products and other ingredients. It locks in freshness and nutrients, supports batch continuous operation, and is suitable for the quick-freezing process in slaughter/food processing lines.

frozen storage:

- 18℃

For long-term storage of frozen ingredients. It maintains a stable low-temperature environment to prevent food spoilage, ideal for bulk frozen product storage in food processing plants and cold chain warehouses.

Carcass acid - removal /cold room: 0 - 4℃

For post-slaughter carcass acid removal and pre-cooling. It improves meat texture and safety, serving as a core quality-enhancing step in meat processing, and is suitable for post-treatment processes in slaughter lines.